The use of biodegradable materials in medical injection molding has gained significant attention in recent years, as medical equipment parts companies strive to adopt environmentally sustainable practices. This article will explore the growing trend of using biodegradable materials in medical injection molding and highlight the benefits and challenges associated with this eco-friendly approach.

A Sustainable Solution: Biodegradable Materials in Medical Injection Molding

The adoption of biodegradable materials in medical injection molding offers medical equipment parts companies a sustainable solution that aligns with their commitment to environmental conservation. These materials can break down naturally when exposed to specific conditions, reducing their impact on the environment and promoting a circular economy.

Meeting Industry Standards: Biocompatibility and Performance

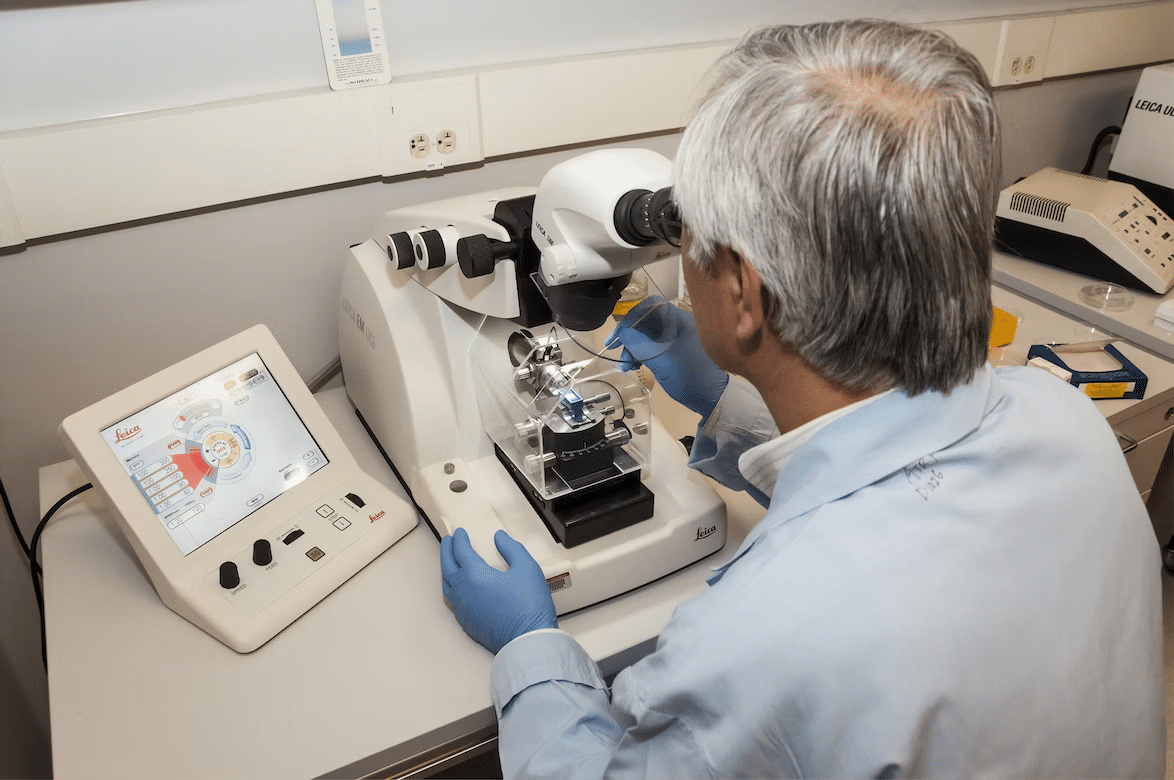

Medical equipment parts companies prioritize the use of biocompatible materials in order to meet industry standards and ensure patient safety. Biodegradable materials specifically developed for medical injection molding must undergo rigorous testing to verify their biocompatibility and performance, ensuring they are suitable for use in medical devices and equipment.

Advantages and Applications of Biodegradable Materials in Medical Injection Molding

Biodegradable materials offer several advantages for medical equipment parts company. They can be used to produce a wide range of components, including surgical instruments, implantable devices, and drug delivery systems. Biodegradable materials also offer versatility in terms of mechanical properties and can be engineered to have specific characteristics such as flexibility, strength, and resorbability.

Environmental Benefits: Reduced Waste and Carbon Footprint

The use of biodegradable materials in medical injection molding significantly reduces waste generation and helps to minimize the carbon footprint associated with the production process. By choosing biodegradable materials over conventional plastics, medical equipment parts companies contribute to a cleaner and healthier environment by reducing the accumulation of non-biodegradable materials in landfills.

Challenges and Future Perspectives

While the adoption of biodegradable materials in medical injection molding brings numerous benefits, there are also challenges to address. These challenges may include material availability, cost, and processing compatibility. However, ongoing research and development efforts continue to improve the performance and viability of biodegradable materials, making them a promising choice for medical equipment parts companies in the future.

Finding the Right Supplier: Choosing a Trustworthy Medical Equipment Parts Supplier

When adopting the use of biodegradable materials in medical injection molding, it is crucial for medical equipment parts companies to partner with a reliable and reputable medical equipment parts supplier. The supplier should have expertise in sourcing and providing high-quality biodegradable materials that meet industry standards and regulations, ensuring the production of safe and durable medical components.

Conclusion

The use of biodegradable materials in medical injection molding presents a sustainable and eco-friendly solution for medical equipment parts companies. By incorporating these materials into their production processes, these companies can actively contribute to environmental conservation, reduce waste generation, and minimize their carbon footprint. While challenges exist, ongoing developments and innovations in biodegradable materials offer promising prospects for a greener future in medical manufacturing.